Environmental

At Dry Fork Mine we take environmental responsibilities seriously since we live in the community in which we operate. We comply with a multitude of environmental laws, rules, and regulations while promoting conservation and stewardship of the land by successfully reclaiming areas that have been disturbed by mining.

Dry Fork Mine and CarbonSAFE

“The Carbon Storage Assurance Facility Enterprise (CarbonSAFE) Initiative projects focus on development of geologic storage sites for the storage of 50+ million metric tons (MMT) of carbon dioxide (CO2) from industrial sources. CarbonSAFE projects will improve understanding of project screening, site selection, characterization, and baseline monitoring, verification, accounting (MVA), and assessment procedures, as well as the information necessary to submit appropriate permits and design injection and monitoring strategies for commercial-scale projects. These efforts will contribute to the development of 50+ MMT storage sites in anticipation of injection by 2026.” (CarbonSAFE | netl.doe.gov)

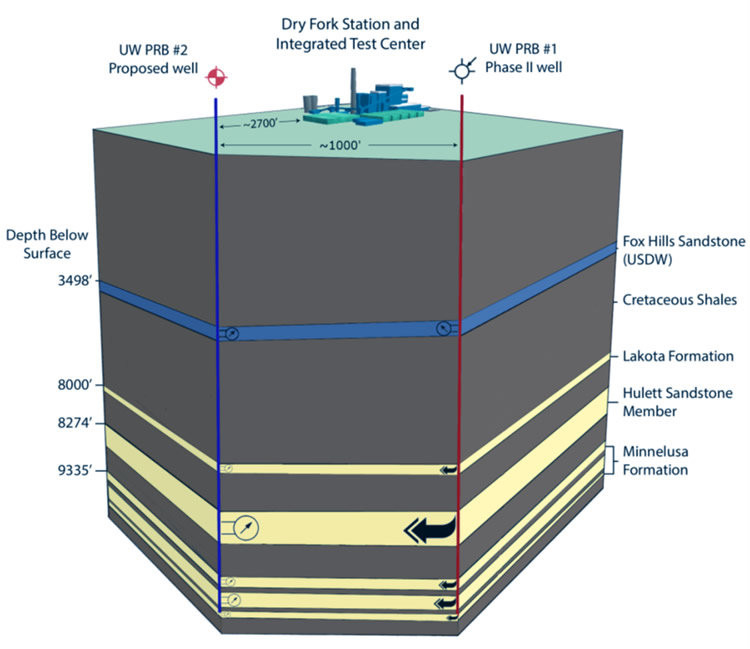

Idealized subsurface 3-D block view of PRB #1 and #2

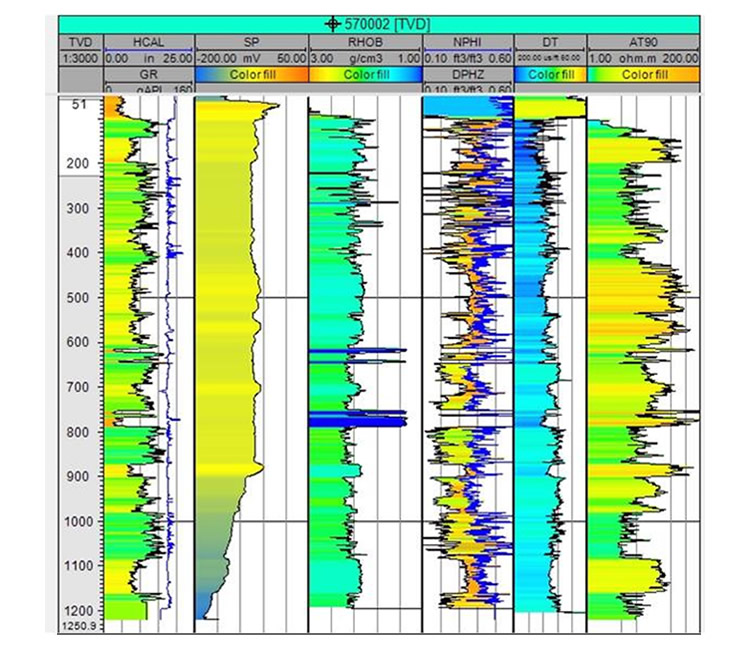

Colorized subsurface geophysical logs showing lithologies and properties.

Western Fuels–Wyoming’s Dry Fork Mine has been an integral part of the Wyoming CarbonSAFE project led by the University of Wyoming’s Center for Economic Geology Research (CEGR) since the project first announced in 2018. Led by UW-CEGR and partnered with Basin Electric Power Cooperative, the project is integral to studying carbon capture, utilization, and storage (CCUS) and holds great promise for the Powder River Basin and local area coal mines.

The project will consist of five phases, and Phases I and II (Integrated CCS Pre-Feasibility and Storage Complex Feasibility, respectively) have been completed and Phase III is currently underway – Site Characterization and CO2 Capture assessment. Wyoming CarbonSAFE Project (uwyo.edu)

An initial test well was drilled in the Spring and Summer of 2019, to begin characterizing subsurface geology and identifying potential geologic formations to test CO2 storage capability. The test well was plugged until the testing and analysis of data could be completed. A second well was recently completed in January 2022, and the plug in the initial well is being drilled out and the hole prepared for injection testing. Classes of Injection Wells

Rare Earth Elements

Rare earth elements (REE) are a set of seventeen chemical elements in the periodic table, specifically the fifteen lanthanides plus scandium and yttrium. Scandium and yttrium are considered rare earth elements since they tend to occur in the same ore deposits as the lanthanides and exhibit similar chemical properties. While named rare earths, they are in fact not that rare and are relatively abundant in the Earth’s crust. What is unusual is to find them in quantities significant enough to support economic mineral development.

The Japanese call them “the seeds of technology.” The US Department of Energy calls them “technology metals.” They make possible the high tech world we live in today – everything from the miniaturization of electronics, to the enabling of green energy and medical technologies, to supporting a myriad of essential telecommunications and defense systems. They are the elements that have become irreplaceable to our world of technology owing to their unique magnetic, phosphorescent, and catalytic properties. www.rareelementresources.com

Domestic production of REE is at an all-time low, with most production occurring in China at 58% with the next closest the US at 16% (Statista.com, 2020 numbers). With so many current technologies requiring REE as part of their own production process and most REE production from overseas, President Donald Trump signed Executive Order 131817 in 2018 to help secure reliable, domestic sources of REE and critical minerals (CM).

Rare earth elements include: lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu), scandium (Sc), and yttrium (Y).

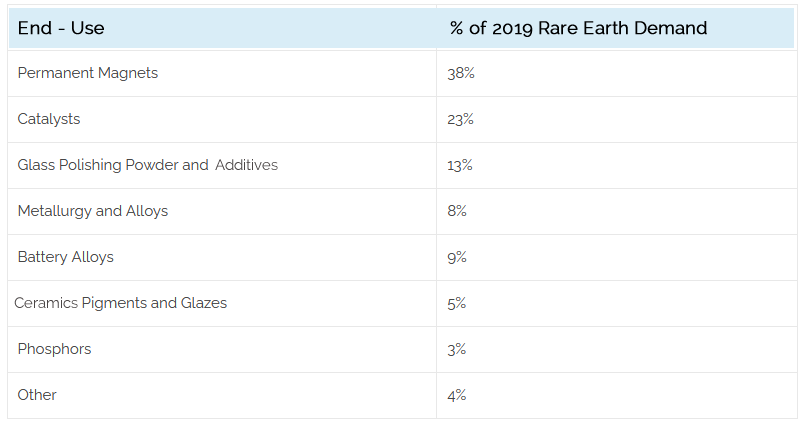

How are REEs used in modern technology? Various products including electronics, glass, ceramics, catalysts, metal alloys, and magnets utilize REE in their design, production and use.

From Rare earth elements: Where in the world are they? – MINING.COM

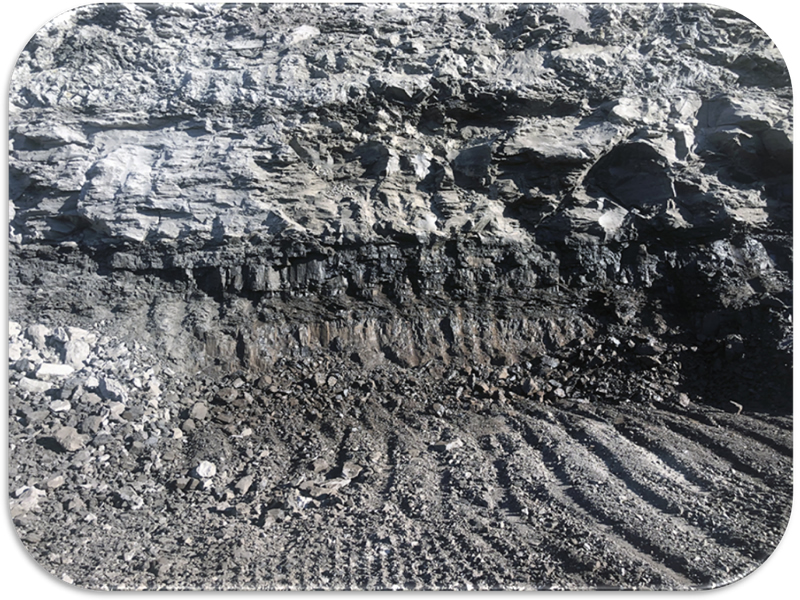

Dry Fork Mine and Powder River Basin Coal

Preliminary research indicates that waste stream materials (non-economic coal at the tops and bottoms primary recovered coal seams and parting interburden) produced by Dry Fork Mine contain recoverable and marketable quantities of REEs. In addition to material from mining, coal bottom ash produced by coal burned at local power plants also contain notable concentrations of REE.

Currently, these materials are buried in the pit during the pit backfilling process after coal has been extracted. This source could be a viable alternative to foreign sources of REE minerals, increasing strategic independence for the United States. In addition, possible marketable REE recovery from the waste coal and bottom ash could be extremely beneficial for Powder River Basin and Wyoming economies.

April 2021 DOE awarded $19m for 13 CORE-CM projects. Federal Register :: A Federal Strategy To Ensure Secure and Reliable Supplies of Critical Minerals

Program-141_0.pdf (doe.gov) NETL DOE website on REE-CM

An Overview of Rare Earth Elements and Related Issues for Congress

Critical Materials Rare Earths Supply Chain: A Situational White Paper (energy.gov)

Rare Earth Elements (rareelementresources.com)

Critical Minerals of the United States | U.S. Geological Survey (usgs.gov)