Safety

Key Safety Philosophies at Dry Fork Mine

Safety is a core value at Western Fuels-Wyoming, Inc.’s Dry Fork Mine. Employees routinely work on and in heavy equipment, moving vehicles, pressurized pipes and under other conditions that require exceptional safety measures and awareness.

Zero Harm at Work and at Home

At Dry Fork Mine, our goal is a culture where all employees clearly demonstrate a positive attitude, belief, commitment, and accountability for their own safety and the safety of their co-workers at all times, and that safety excellence is no less important than productivity or quality. Our goal is world class safety performance, achieved by “Zero harm at work and at home.”

“Zero harm at work and at home” is not just about numbers; it is about people – striving to ensure a culture of sustainable safety excellence through visible leadership and accountability, while empowering our workforce to make impactful decisions that lead us to become an organization with zero incidents, so everyone goes home safe every day.

Dry Fork Mine’s Journey to Safety Excellence

Dry Fork Mine has had what would be considered a successful safety program since its inception. However, in 2016 Dry Fork Mine embarked on a journey to Safety Excellence. Dry Fork Mine implemented a safety program that is employee driven. A contest was held amongst employees to name our new safety process. The winning entry was Coworkers Helping Achieve Safety Excellence, or C.H.A.S.E.

The C.H.A.S.E. safety process works by engaging Dry Fork Mine’s workforce by asking them to identify and address safety concerns. This is achieved by forming groups called Continuous Improvement, or C.I. Teams. The belief was, and continues to be, that employees who perform the work are best suited to identify safety issues and develop solutions to address them.

Every employee completed a safety survey to determine areas where improvements could be made to advance our safety culture. Communication was the first topic chosen based on the survey response. Therefore, C.I. Team 1 was formed, which led to the development of the Personal Safety Interaction, or P.S.I. process. This process opened the lines of communication between Dry Fork Mine’s management and hourly workforce and has been a very beneficial part of improving our safety culture.

A total of twelve Continuous Improvement Teams have been formed to date, and the current percentage of participation from the workforce is at 88%. Each C.I. Team has addressed a subject or process identified by the Steering Committee, which mostly consists of hourly employees. The subjects that have been addressed included issues that Dry Fork Mine’s workforce believed could be improved upon by a C.I. Team. In addition, they have also developed our yearly goals for the mine.

The safety culture at Dry Fork Mine has greatly improved since the implementation of this process, which is directly attributed to the participation of every employee at Dry Fork Mine.

WFA-Dry Fork Mine 2018 Safety Award-Department of Workforce Services Safety Summit

SELECT FROM THE TITLE BELOW TO VIEW

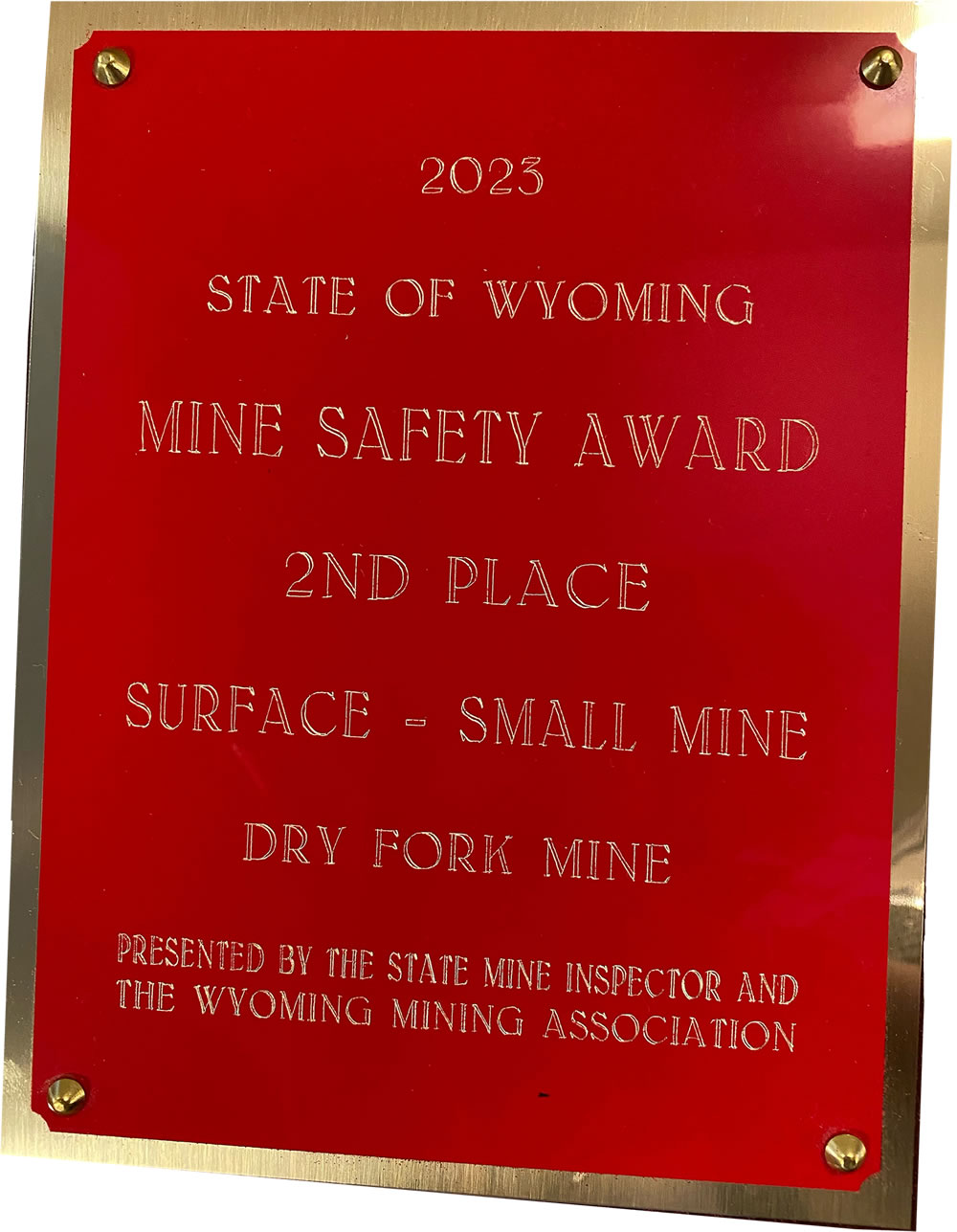

2023 State of Wyoming Surface Mine Safety Award

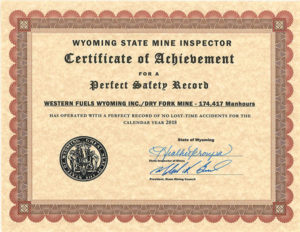

2023 Perfect Safety Record